Restoration Chronology

|

September 22nd, 2021Although destined for the Québec Aerospace Museum (QAM), the AFSG-1 ground power unit (GPU) disappeared at the École nationale d'aérotechnique (ÉNA). It was eventually rediscovered in one of the school's recycling bins. |

|

|

September 22nd, 2021Without delay and before it disappeared forever, the GPU was recovered and saved with the help of an ÉNA helper. |

|

|

September 22nd, 2021Heavy equipment is used to extract the GPU from the recycling dumpster! Fortunately, it seems to have survived the abuse well. It must be the result of its rugged military design! |

|

|

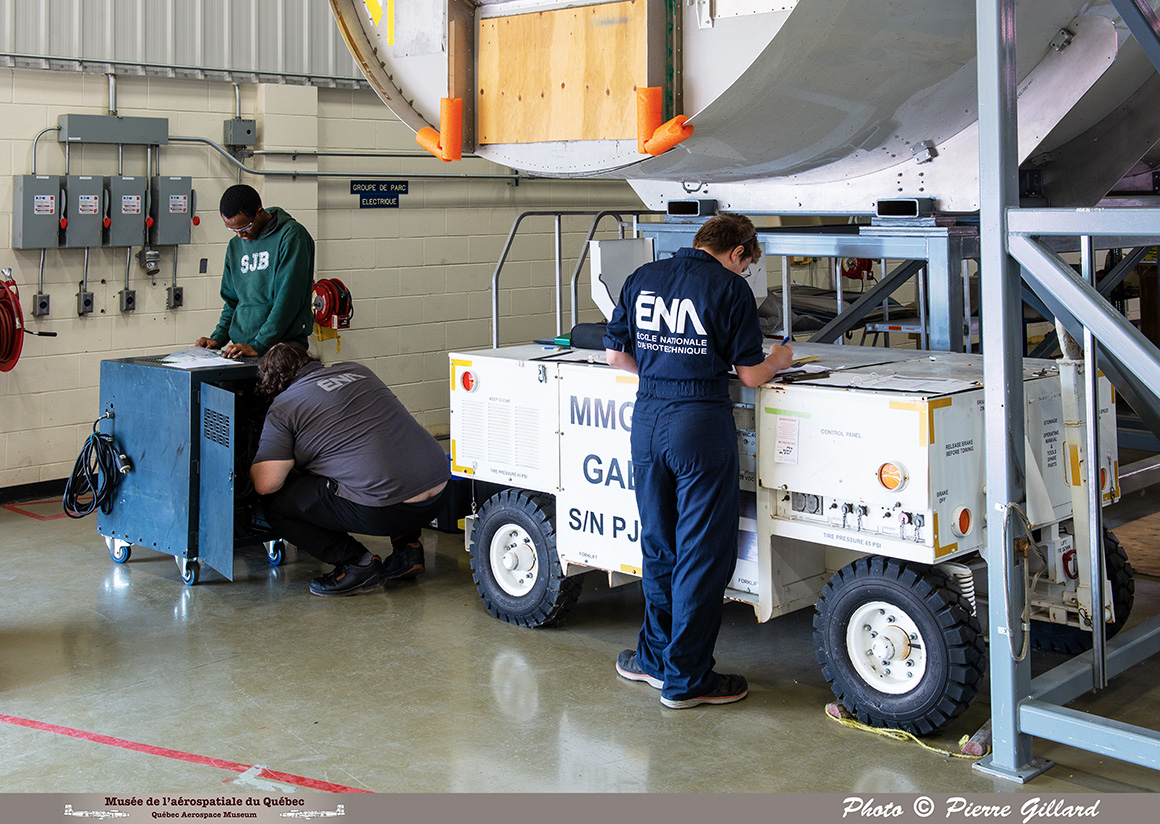

September 8th, 2022A little less than a year has passed without much progress on the restoration of the GPU as a result of the pandemic. However, with the return to normal in 2022, an agreement was reached with ÉNA that the repair of the GPU will be entrusted to the "Électro-ÉNA" student group, under the supervision of Jean-François Daigle, a professor in the Avionics Department. A first inspection is carried out: cleaning is essential before any work starts! |

|

|

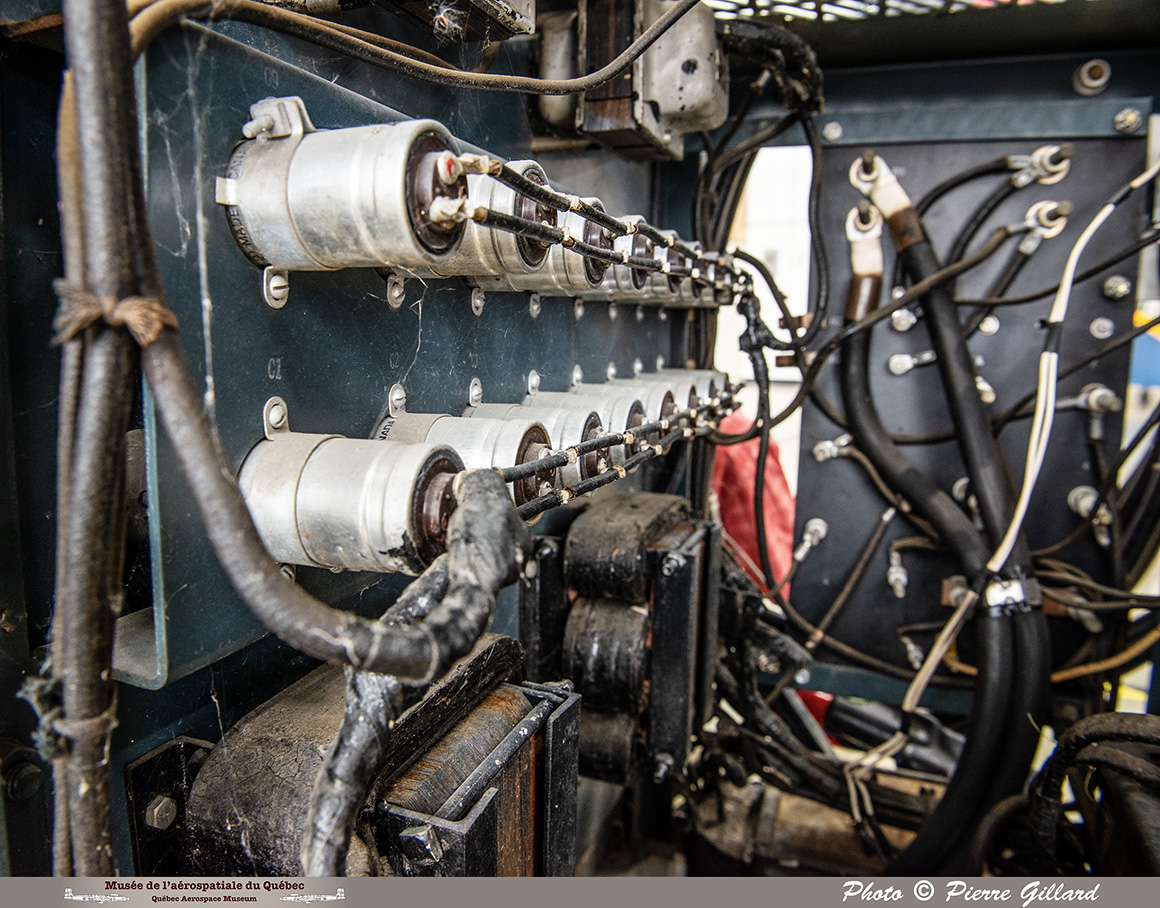

September 8th, 2022The GPU dates from 1952 and the filter capacitors mounted in parallel in two groups must to be replaced. In fact, during its last use we discovered the capacitors did not hold the voltage once loaded. |

|

|

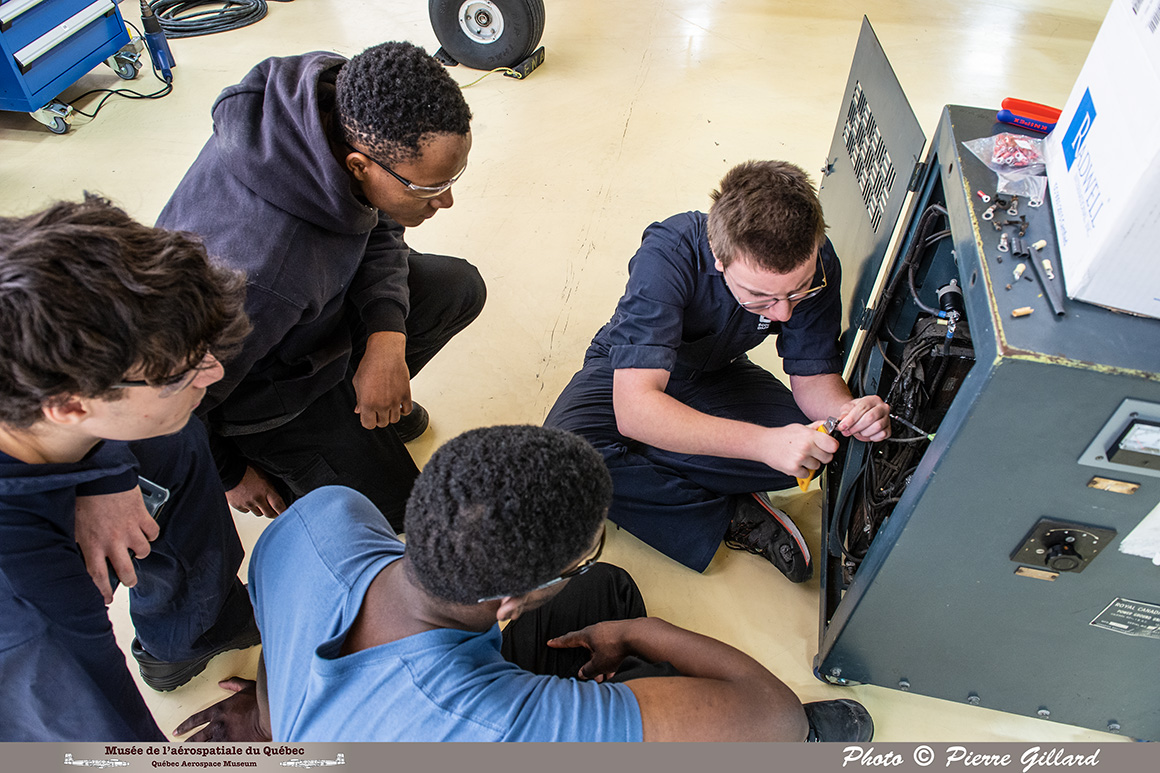

September 14th, 2022Work began today cleaning of the interior. The students of the "Électro-ÉNA" group are very motivated to carry out this restoration project. Following the cleaning, we decided to keep the original wiring which, despite its age, remains in good condition. |

|

|

October 5th, 2022The project continues on free periods on Wednesdays which are dedicated ÉNA student groups. Several non-compliant modifications were noted and work cards drawn up to identify the tasks required. The goal is to place the students in a work environment that is very similar to an MRO (Maintenance & Repair Organization). Some soldering work was undertaken near the capacitors in order to identify their nominal capacity and replace them. |

|

|

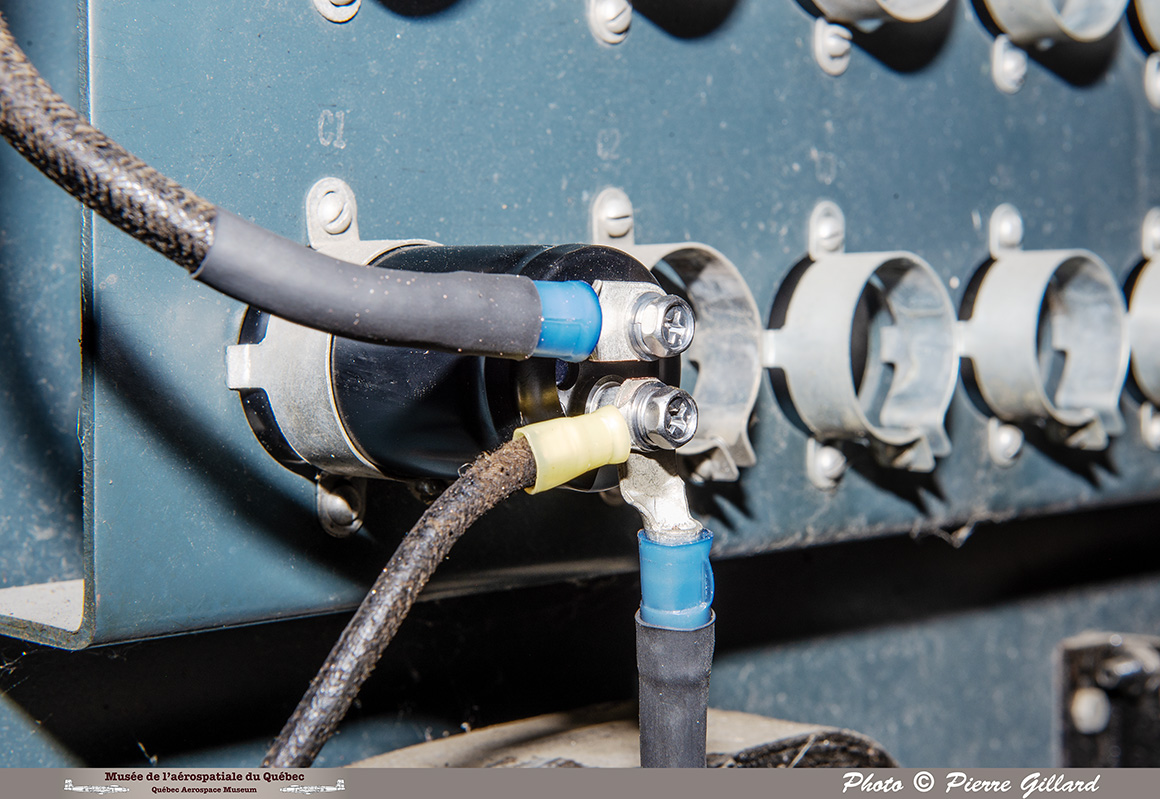

October 19th, 2022New 14 VDC and 28 VDC power cables of 4 AWG gauge, as well as connectors, are prepared. This operation requires soldering with a gauge of electrical wire that students are not used to handling in their course. Having students learn new techniques that are not part of their academic program is one of the goals of this QAM project. |

|

|

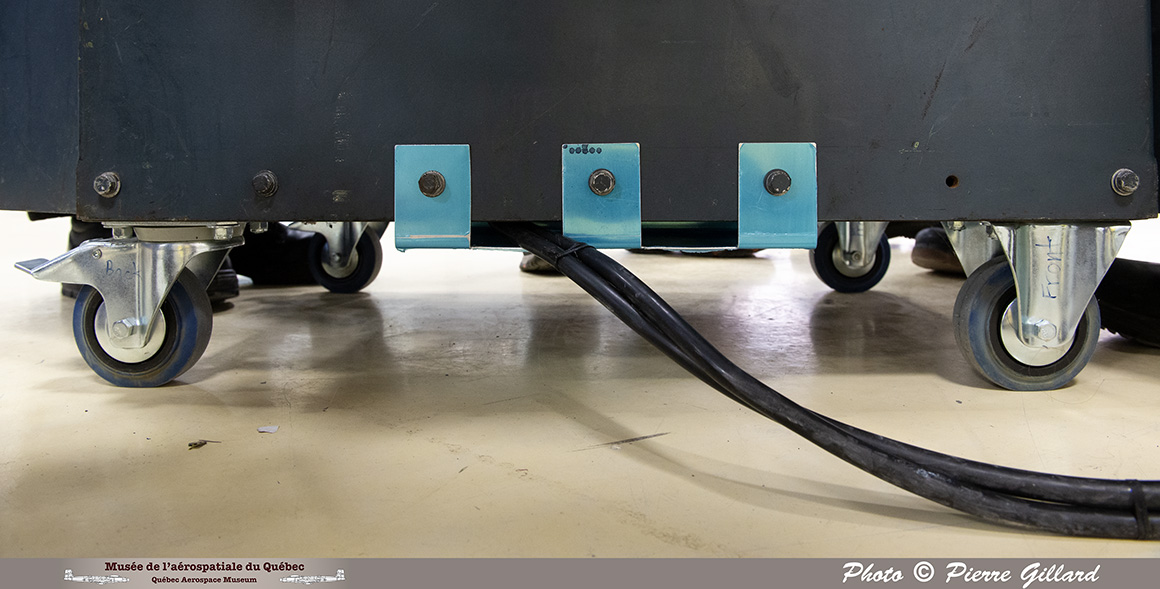

November 2nd, 2022New wheels are installed on the GPU. These will be able to allow a more flexible and, above all, quieter (!) movement of the device. It’s now more useful and much quieter to move. The students from the avionics program are learning practical mechanical skills they can use later in their careers. And they are doing very well! |

|

|

November 9th, 2022Two DC power cables are bundled in pairs using the waxed lacing cord technique. |

|

|

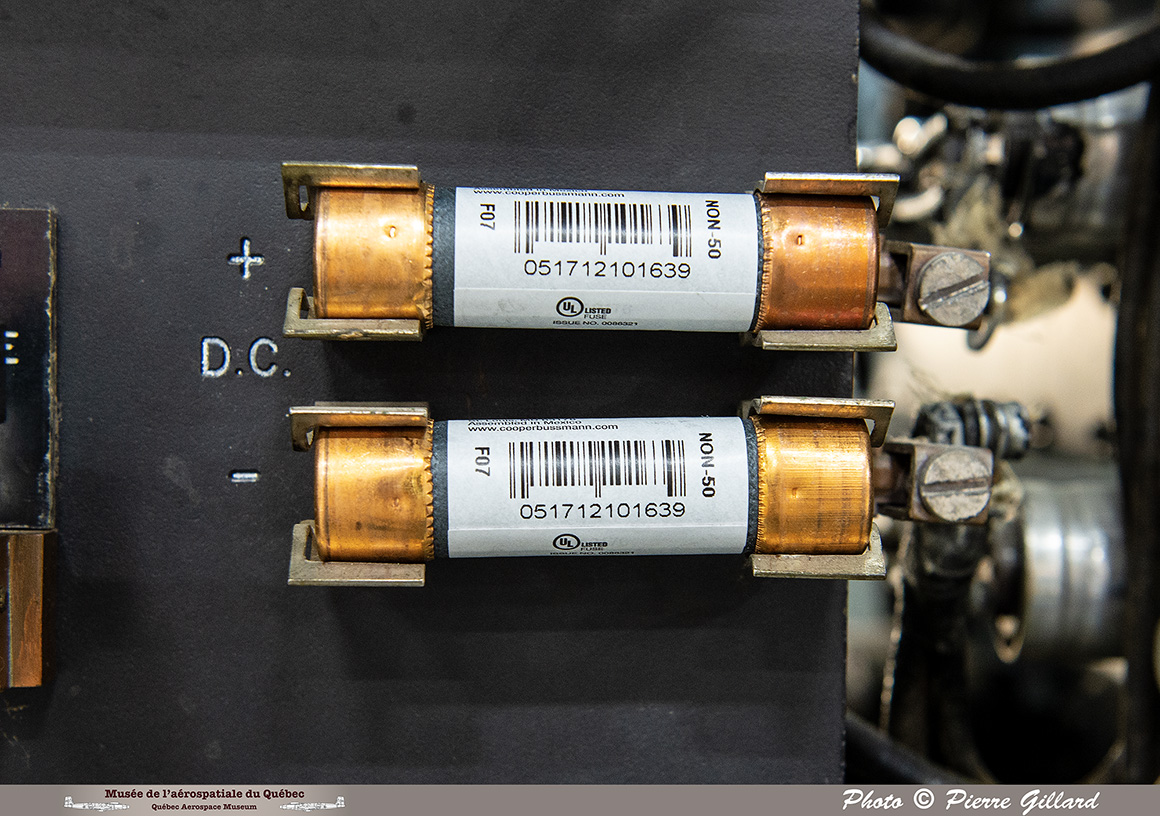

November 9th, 2022Two 50 amp fuses are installed to replace two others which were of too high a rating and therefore non-compliant. These protect the 28 VDC output. |

|

|

November 23rd, 2022Originally, the GPU had two banks of eight 2,000 µF capacitors connected in parallel. We eventually found a 22,000 µF capacitor that can be mechanically installed in place of one of the original capacitors. This is a good example of how electronic components have evolved and become smaller since 1952! |

|

|

November 23rd, 2022The students had to use both mechanical and hydraulic crimpers to attach new terminals on the wires connected to the two capacitors. |

|

|

December 7th, 2022After all security checks are performed, the GPU is powered with an open circuit output. Everything works perfectly both at 14 VDC and at 28 VDC. Needless to say, the students of the "Électro-ÉNA" group are very proud of the positive result which coincided with the end of their semester. This is a great end to the year! |

|

|

Frebruary 15th, 2023To begin this new session, two students dismantled the old damaged ammeter and its shunt. |

|

|

March 29th, 2023Today a student installed a new ammeter on a support manufactued by Professor Symon Blanchet. It remains to complete the replacement of the 50 mV shunt by a 75 mV and to wire the indicator. |

|

|

April 18th, 2023The new 75 mV shunt is installed on the bakelite support of the former 50 mV-one. |

|

|

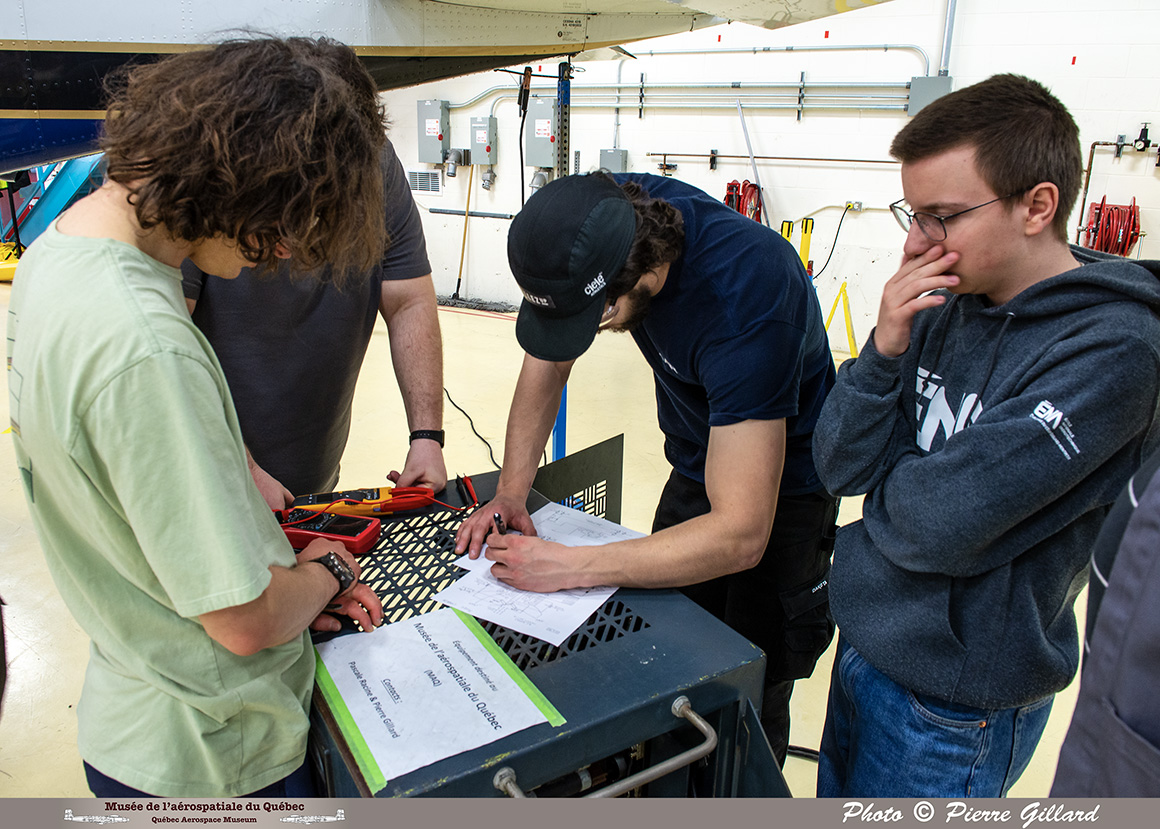

September 13th, 2023Upon returning from vacation, students from the “Avionics” group at the École nationale d'aérotechnique evaluated the work remaining to be carried out on the GPU. |

|

|

September 27th, 2023Looking for a FOD that fell behind a partition in the GPU. |

|

|

October 18th, 2023Students carried out the installation of the ammeter shunt in the GPU. |

|

|

November 1st, 2023A student from the Aerospace Engineering Techniques program, having joined the "Avionics" group, completed the design of a part to support the DC output cables of the GPU by using CATIA software. |

|

|

November 1st, 2023At the same time, the 120V power indicator is installed on the GPU. |

|

|

November 15th, 2023Today, terminals were installed on the ammeter and shunt wires. This was an opportunity for first-session students in the Avionics Program as well as for the student in the Aerospace Engineering Program to learn about crimping. By-the-way, because the GPU is wired with old wire, "technical adaptations" are sometimes necessary! |

|

|

December 6th, 2023The 28V output cables were installed. A test was then carried out on an aircraft, but it was found that the capacity of the capacitors was too low. A calculation was then carried out and new capacitors will have to be ordered. Indeed, until then, we had relied on indications found on the old capacitors. Clearly, these indications were not the right ones! The new capacitors would be installed upon return after the holidays. |

|

|

February 28th, 2024The new capacitors have been delivered and two students installed them using the existing fasteners. |

|

|

March 6th, 2024All the students were called upon to make 28 AWG 8 gauge jumper wires necessary to connect all the capacitors in parallel with each other. Some took care of stripping the wires and others crimping the terminals using hydraulic pliers, a tool that the students are not used to using regularly. |

|

|

March 6th, 2024The first wires were installed on the capacitors at the end of the activity. The others will be for the next working session. |

|

|

March 20th, 2024The last jumper wires were installed on both rows of capacitors. This work required a certain flexibility and dexterity! |

|

|

March 20th, 2024Then came the time for a test on a Cessna 421. The external power plug was connected, but when we put the GPU on, it was noticed that half of the DC power supply was not able to maintain the voltage under load. Small disappointment for the group, but an excellent troubleshooting exercise ahead! |

|

|

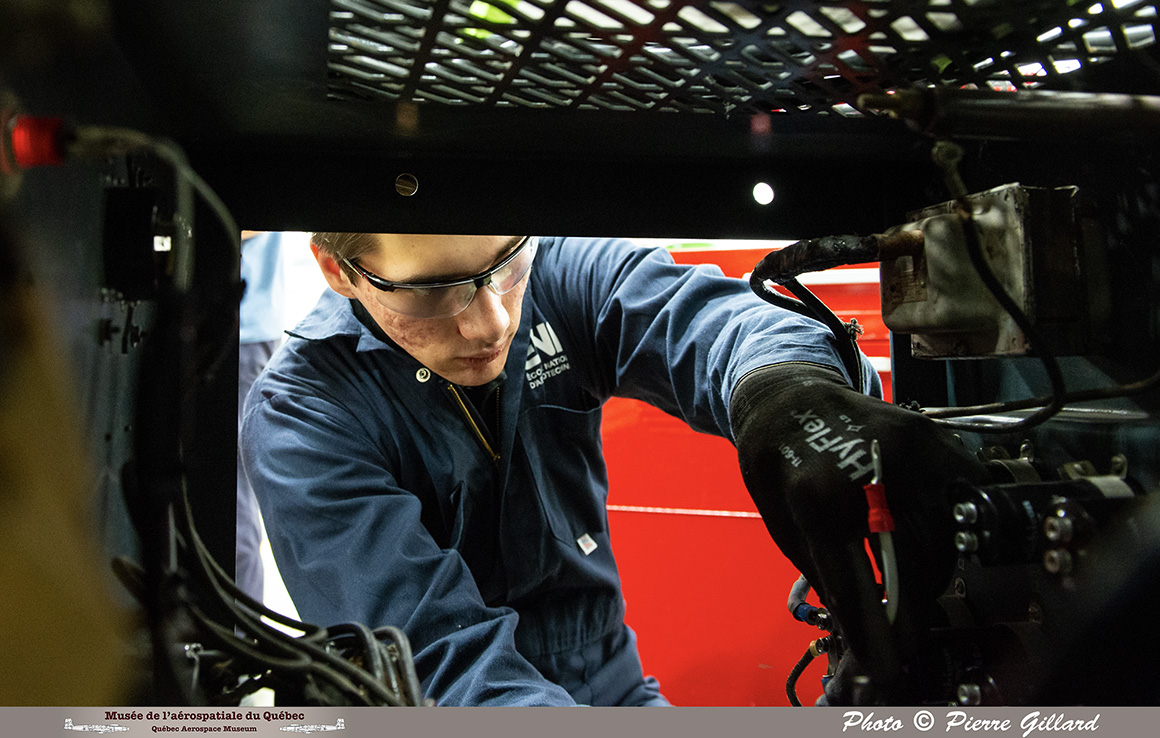

April 10th, 2024Investigations to discover the origin of the problem began. A training device simulating an aircraft electrical circuit was used as an electrical load for the GPU. |

|

|

April 10th, 2024Measurements were taken and the results shown on a printout of the GPU electrical schematic. Clearly, one of the two 14 VDC power supplies had a problem causing its output voltage to drop. |

|

|

April 10th, 2024A test was carried out with the plate intended to support the DC output cables. Alexis, the student in the aerospace engineering techniques program, carried out precision work because everything was placed perfectly without any adjustment! It now remains to finish the work, in particular, adding ties for the cables. |

|

|

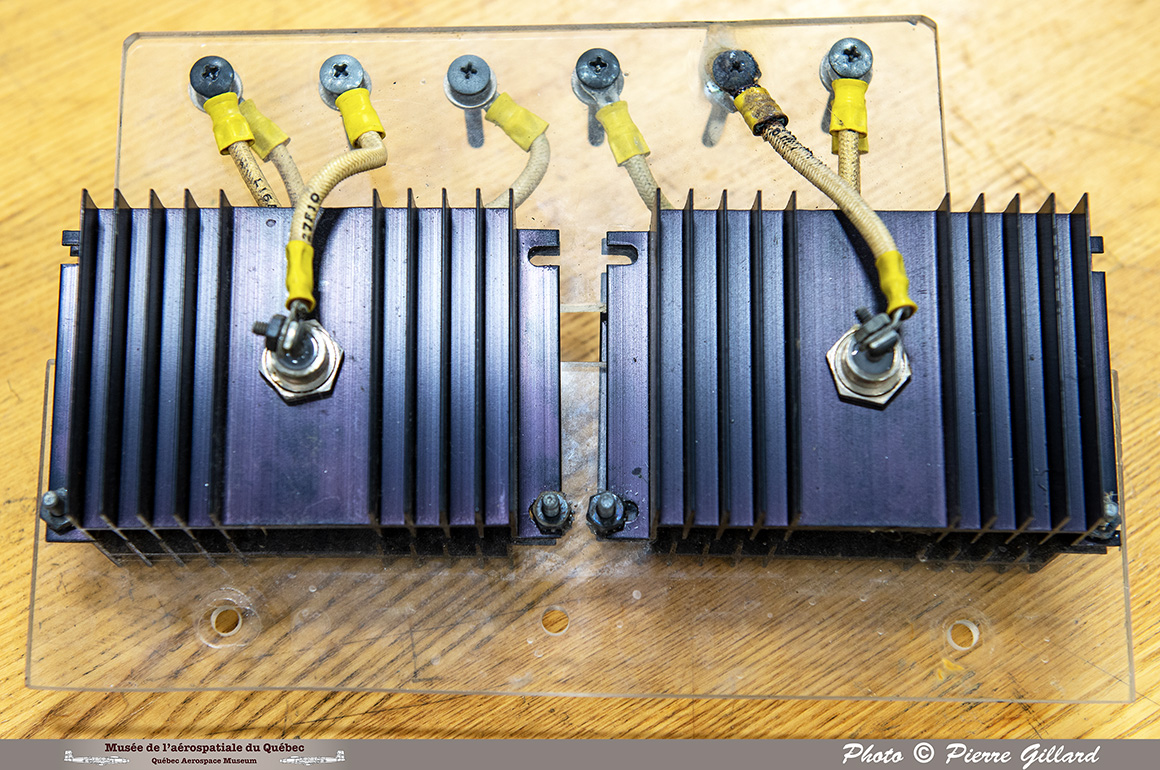

April 24th, 2024By disassembling the rectifier module with the four power diodes, the problem was found on a stud which had literally burned. It must be said that the six studs were not made correctly and that the assembly looks more like DIY than professional work. This was most certainly carried out at some point to replace the four original diodes which were selenium (not very good for health and nature!) with recent power diodes. Indeed, semiconductors were not yet used in electrical and electronic circuits when the GPU was built in 1952. |

|

|

May 1st, 2024Jérémie, one of the students in the group, under the supervision of Professor Martin Leduc, worked on repairing the rectifier module. At the moment only the studs and the burnt wire were replaced. This would allow validation tests of the repair to be carried out before considering creating a new, slightly more professional-looking support. |

|

|

May 1st, 2024The rectifier module was ready to be reinstalled in the GPU after its temporary repair. |

|

|

May 1st, 2024Simultaneously, during the repair of the rectification module, students prepared a set of power cables which will allow the GPU to be connected to several models of power sockets available at ÉNA or elsewhere. |

|

|

May 8th, 2024Assembling of the power cable set continued. For many students, this is the first time they had worked with domestic electrical plugs and sockets! |

|

|

May 8th, 2024At the same time, Nicolas, a student in the group, replaced the rectifier module in the GPU. An inspection was carried out and everything appeared ready for another test. |

|

|

May 8th, 2024The test was carried out on a training device simulating an aircraft electrical circuit in one of the ÉNA laboratories and it was conclusive. The GPU maintained voltage under load. Obviously, the students were very proud to reach the end of their sentence after several work sessions! This project represents a unique opportunity for them to increase their experience as well as their manual dexterity. It is also a good tool intended to promote academic perseverance. |

|

|

September 25th, 2024The GPU being functional, the small details could be completed. Thus, our student from the ÉNA Aerospace Engineering Techniques Program prepared the assembly of clamps on a support plate for the DC output cables. |

|

|

September 25th, 2024Shortly after, the students completed the assembly of the support plate for the output cables. In the meantime, the second output cable was added. |

|

|

November 13th, 2024Some “cosmetic” work were carried out to make the GPU presentable for the next ÉNA open day. |

|

|

November 13th, 2024Even if there are still a few small details to be completed, the AFSG-1 GPU is now considered as operational. |

|

Collaborators on the AFSG-1 GPU project:

|

Students: Calvin ALVES, Alexis BÉCOTTE, Justin BLANCHETTE, Laurier BOIVERT, Mathis CORDEAU, Mac Kevin EBONGUE ETAM, Ayoub EL GHOUDANE, Mathis GRAVEL, Alexis LEMIEUX, Jérémie LEPAGE, Yacine MASROUKI, Martin Kamuanya MUDIMBI, Leo O'HARE, Alexandre PODGORNOV, Alexander SCIORTINO, Ahmed Amine SEGHIOUER, Bryan Landrich TCHOCNING KAMKUI, Cédric TREMBLAY, Nicolas van het HOOG, Yohan VIGNEUX-DESCHÊSNES, and Yannis YAHIATENE. Professors: Symon BLANCHET, Jean-François DAIGLE, Martin LEDUC, Fannie THIBODEAU. QAM Technical Representative: Pierre GILLARD. |

Partners supporting the project:

|

All photos of AFSG-1 GPU restoration work.

Back to the Ground Support Equipment page.

Last update: 14-11-2024.

© Pierre GILLARD, Pierre MÉNARD & Kenneth SWARTZ