|

|

The MMG-1A is a small, compact, trailer-mounted, electric motor-driven generator set (MEPP-Mobile Electric Power Plant). It provides 60 KVA of power under 115/200-volt, 3-phase, 400-hertz AC, and 500/1,000-ampere 28-volt DC power for aircraft maintenance, calibration, and support. Operation of the unit requires a 3-phase, 60-hertz, 220- or 440-volt external power source. The 30-foot input and output cables are stowed in compartments in the rear and left front side of the unit. It was used by the U.S. Navy both aboard ships (including aircraft carriers) and ashore. The MEPP is not self-propelled and must be towed or manually moved. The 4-wheel trailer is equipped with tie-down rings, pneumatic tires, a mechanical hand brake, and a tow bar for towing and steering.

The QAM’s MMG-1A, bearing serial number PJC084, seems to be in good general condition even if it is no longer able to function normally. It will be able to supply QAM aircraft with both alternating current and direct current once repaired and declared perfectly functional.

The QAM’s MMG-1A MEPP was donated by the École nationale d'aérotechnique in Saint-Hubert, QC. It is currently being restored to working order as part of student activities at the school with the financial support of Bell Textron Canada, Mirabel, QC.

Restoration Chronology.

Pictures.

In Service ...

It is not easy to find photos of MMG-1A mobile electrical power plants in action. However, if you look closely at certain official photos of the U.S. Navy, it is sometimes possible to see them in the background as in the few images below:

An MMG-1A mobile electrical power plant is visible in this photo to the right of the C-2A Greyhound aircraft.

Original caption: A Sailor directs a C-2A Greyhound assigned to Fleet Logistics Support Squadron 40 aboard the Nimitz-class aircraft carrier USS George Washington. George Washington is participating in Partnership of the Americas 2008, a multinational exercise designed to enhance regional security and interoperability with maritime partners (US Navy photo/Petty Officer 3rd Class Ian Schoeneberg). |

We can note an MMG-1A mobile electrical power plant on the left in the background of this picture.

Original caption: PACIFIC OCEAN (March 26, 2007) - A group of distinguished visitors (DV) from the Republic of Korea depart from the flight deck of the Nimitz-Class aircraft carrier USS Ronald Reagan (CVN 76) after observing flight operations. The guest were brought aboard for a tour in an effort to familiarize them with aircraft carrier operations and to allow them to see first hand what Ronald Reagan Sailors do on a daily basis. Ronald Reagan is participating in Exercise Reception, Staging, Onward Movement and Integration/Foal Eagle (RSOI/FE) 2007. The exercise demonstrates the U.S. commitment to the ROK/U.S. alliance and enhances combat readiness of ROK and U.S. supporting forces through combined and joint training. U.S. Navy photo by Mass Communication Specialist Seaman Joe Painter (RELEASED). |

We can see, on the left in the background, an MMG-1A mobile electrical power plant.

Original caption: PACIFIC OCEAN (July 11, 2008) Aviation Structural Mechanic 2nd Class Wesley Goodwin, of Flint, Mich., performs maintenance on the arresting hook of a Strike Fighter Squadron (VFA) 195 F/A-18C Hornet in the hangar bay of the aircraft carrier USS Kitty Hawk (CV 63). Kitty Hawk is participating in the 'Rim of the Pacific' exercise with other U.S. units and with units from Australia, Chile, Japan, the Netherlands, Peru, South Korea, Singapore and the United Kingdom. U.S. Navy photo by Mass Communication Specialist 3rd Class Patrick Heil (Released). |

We can note an MMG1-A mobile electrical power plant at the top right of the picture.

Original caption: Sailors assigned to the Weapons Department aboard the aircraft carrier USS Nimitz raise ordnance on the weapons elevator in the hangar bay for an offload. Nimitz is conducting blue water operations in the U.S. 3rd Fleet area of responsibility. (US Navy photo/Petty Officer 3rd Class Peter Merrill). |

Reverse Engineering

Having no operating diagram and only a few pieces of information gleaned here and there, a reverse engineering process is initiated. Indeed, before undertaking any test or repair, it is imperative to fully understand the operation of each of the circuits and components of the device.

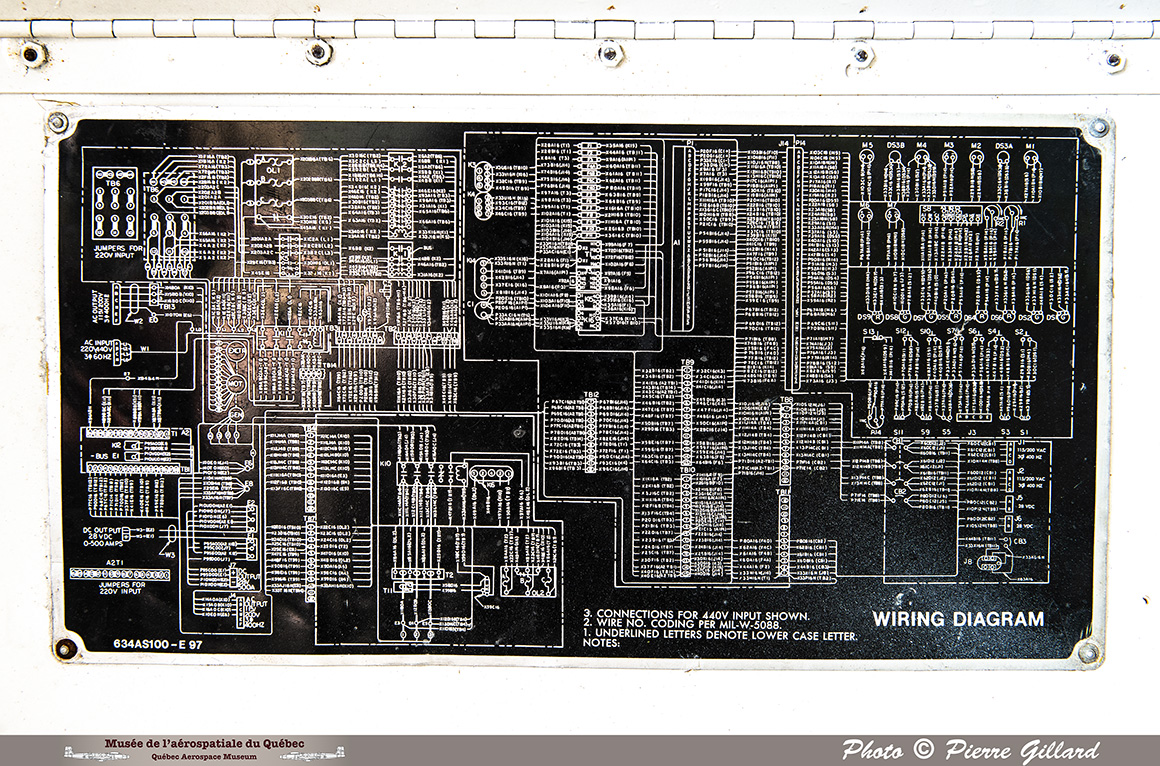

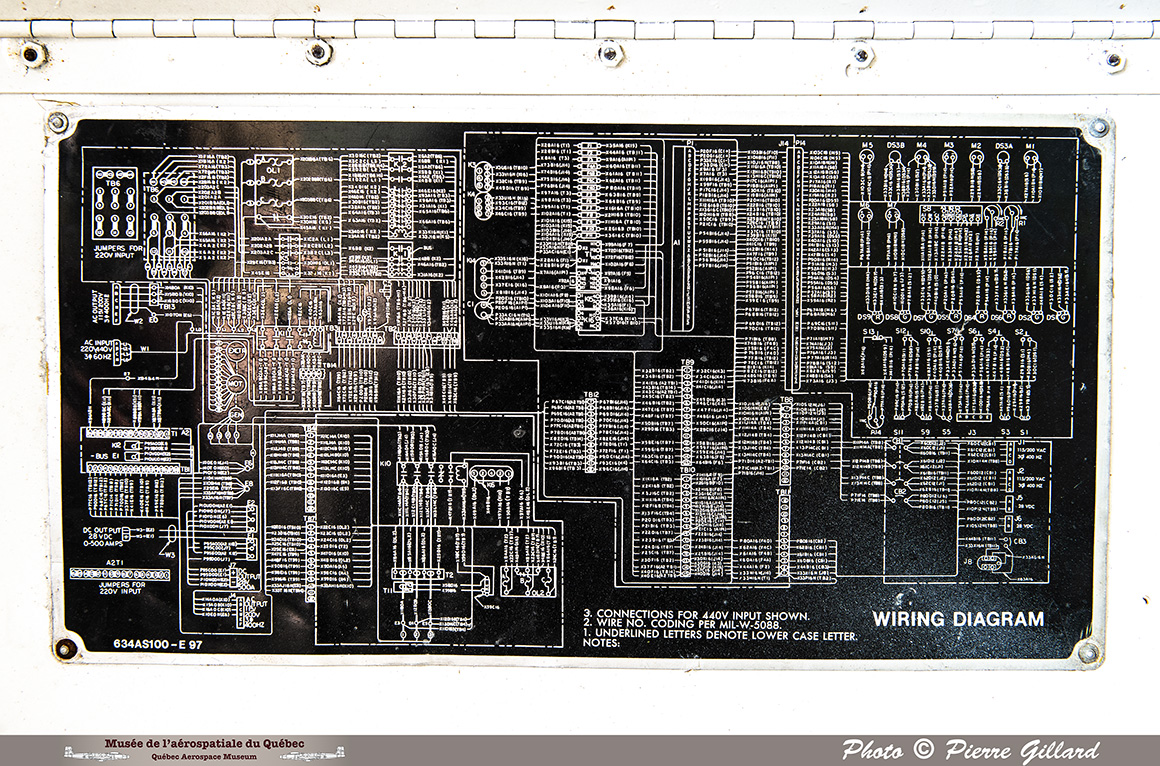

| Diagrams are drafted following observation of the circuits and thanks to the wiring diagram present on the MMG-1A. They are then redrawn in clean computer format. |

This operation is simply visual: each wire is followed from one component, circuit or system to another using the only wiring diagram which is available in the form of a plate riveted to the hatch access to the MMG-1A controls. Often, it is necessary to disassemble one or another part or component in order to follow the path of an electrical circuit. As the investigation progresses, operating diagrams are drawn in rough form by hand, then redrawn neatly in computer format. These then lead to an understanding of all the electrical circuits of the MEPP.

| The only usable diagram is the wiring diagram available in the form of a plate riveted to an access hatch. It's obviously better than nothing at all... |

For ÉNA students, this is a unique opportunity to carry out an activity that is completely complementary to what they are taught in their courses. However, the knowledge acquired during their training will be very useful to them in the context of this reverse engineering process and in understanding how the MMG-1A works.

| For ÉNA students, this MEPP MMG-1A operational restoration project represents a real opportunity to increase their experience and knowledge as well as improve their manual dexterity. |

|